MPSC Deputy Engineer (Mechanical) Gr A Syllabus PDF

MPSC Mechanical Gr A And GR B Syllabus PDF: महाराष्ट्र लोकसेवा आयोग (MPSC) उप अभियंता (यांत्रिक) गट अ परीक्षेचा अभ्यासक्रम आयोगाद्वारे उपलब्ध करून देण्यात आलेला आहे . ही परीक्षा तांत्रिक आणि अभियांत्रिकी ज्ञानासह जनरल स्टडीजवर आधारित असते, त्यामुळे अर्जदारांना संपूर्ण अभ्यासक्रम जाणून घेणे आवश्यक आहे. तसेच या संदर्भातील पुढील सर्व अपडेट्ससाठी या लिंक वरून आपण आमच्या टेलिग्राम चॅनलला जॉईन करावे किंवा या लिंक वरून महाभरती एक्सामची अधिकृत अँप आपल्या मोबाईल मध्ये डाउनलोड करावी आणि अधिक ताज्या आणि अधिकृत महाराष्ट्र परीक्षेच्या अपडेटसाठी MahaBharti.in/exam फॉलो करा:

⏰MPSC Electrical Engineering Services Syllabus And Exam Pattern

MPSC Civil Engineering Syllabus And Exam Pattern

MPSC Civil Engineering Syllabus And Exam Pattern

MPSC Deputy Engineer (Mechanical) Group A Exam Pattern

MPSC उप अभियंता (यांत्रिक) गट अ परीक्षा योजना

| परीक्षेचे टप्पे | गुण | कालावधी | माध्यम | प्रश्नपत्रिकेचे स्वरुप |

|---|---|---|---|---|

| लेखी परीक्षा | 200 गुण | 1 तास | इंग्रजी | वस्तुनिष्ठ बहुपर्यायी प्रश्न |

| मुलाखत | 50 गुण | – | – | – |

परीक्षेचा अभ्यासक्रम आणि पद्धत:

- विषय: विषयाशी / विभागाशी संबंधित घटक (पदवी स्तर).

- प्रश्नसंख्या: 100 प्रश्न.

- गुण: 200 गुण.

नकारात्मक गुणांकन:

- प्रत्येक चुकीच्या उत्तरासाठी एकूण गुणांमधून 25% (1/4) गुण वजा केले जातील.

- एखाद्या प्रश्नाचे एकापेक्षा अधिक उत्तरे दिली असल्यास किंवा उत्तरपत्रिकेत पूर्ण वर्तुळ चिन्हांकित केले नसेल तर त्या प्रश्नाचे उत्तर चुकीचे समजले जाईल, आणि त्यावर 25% (1/4) गुण कमी केले जातील.

- अंतिम गुणांची बेरीज अपूर्णांकात आली तरी ती अपूर्णांकातच राहील.

- एखाद्या प्रश्नाचे उत्तर अनुत्तरित असेल तर नकारात्मक गुणांकन लागू होणार नाही.

अंतिम गुणवत्ता यादी:

अंतिम गुणवत्ता यादी ही लेखी परीक्षेतील आणि मुलाखतीतील एकत्रित गुणांवर आधारित असेल.

MPSC Deputy Engineer Mechanical Group A Syllabus 2024

MPSC Deputy Engineer (Mechanical) Gr A Syllabus – Topics and Sub-topics Details

| Sr. No. | Topic | Sub-topics |

|---|---|---|

| 1 | Current Affairs (Indian and Global) | Scientific, Political, Industrial, Economic, Social, Educational, Geographical, Astronomical, Cultural, etc. |

| Acts and Laws | Right to Information Act-2005, Maharashtra Right to Services Act-2015, Various Labour Laws and Acts (Industrial Disputes Act, Factory Act, Industrial Safety Act, Minimum Wages Act, etc.) | |

| 2 | General Engineering | |

| 2.1 | Engineering Materials | Basic Crystallography, Alloys and Phase Diagrams, Heat Treatment, Ferrous and Non-ferrous Metals, Non-metallic Materials, Basics of Nano-materials, Mechanical Properties and Testing, Corrosion Prevention and Control. |

| 2.2 | Manufacturing, Industrial and Maintenance Engineering | Metal Casting, Metal Forming, Metal Joining, Machining and Machine Tool Operations, Limits, Fits, and Tolerances, Metrology and Inspection, Computer Integrated Manufacturing, FMS, Production Planning and Control, Inventory Control and Operations Research, CPM-PERT, Failure concepts and characteristics-Reliability, Failure analysis, Machine Vibration, Data acquisition, Fault Detection, Vibration Monitoring, Field Balancing of Rotors, Noise Monitoring, Wear and Debris Analysis, Signature Analysis, NDT Techniques in Condition Monitoring |

| 2.3 | IC Engines, Refrigeration and Air Conditioning | SI and CI Engines, Engine Systems and Components, Performance characteristics and testing of IC Engines; Fuels; Emissions and Emission Control. Vapour compression refrigeration, Refrigerants and Working cycles, Compressors, Condensers, Evaporators and Expansion devices, Other types of refrigeration systems like Vapour Absorption, Vapour jet, thermo electric and Vortex tube refrigeration. Psychometric properties and processes, Comfort chart, Comfort and industrial air conditioning, Load calculations and Heat pumps |

| Applied Thermodynamics | Thermodynamic systems and processes, properties of pure substance, Zeroth, First and Second Laws of Thermodynamics; Entropy, Irreversibility and availability, analysis of thermodynamic cycles related to energy conversion: Rankine, Otto, Diesel and Dual Cycle, ideal and real gases, compressibility factor, Gas mixtures. Modes of heat transfer, Steady and unsteady heat conduction, Thermal resistance, Fins, Free and forced convection, Correlations for convective heat transfer, Radiative heat transfer Radiation heat transfer co-efficient, boiling and condensation, Heat exchanger performance analysis |

|

| Turbo Machinery | Reciprocating and Rotary pumps, Pelton wheel, Kaplan and Francis Turbines, velocity diagrams, Impulse and Reaction principles, Steam and Gas Turbines, Reciprocating and Rotary Compressors Theory and Applications |

|

| 3 | Fluid Mechanics – | Basic Concepts and Properties of Fluids, Manometry, Fluid Statics, Buoyancy, Equations of Motion, Bernoulli’s equation and applications, Viscous flow of incompressible fluids, Laminar and Turbulent flows, Flow through pipes and head losses in pipes. Cavitation |

To Get Full Syllabus For MPSC DE Mechanical Group A Click at below link and download full syllabus PDF

Click Here To Download MPSC DE WRD Mechanical Syllabus 2024

महाराष्ट्र यांत्रिकी अभियांत्रिकी सेवा गट A आणि गट B मुख्य परीक्षेचा नमुना आणि अभ्यासक्रम

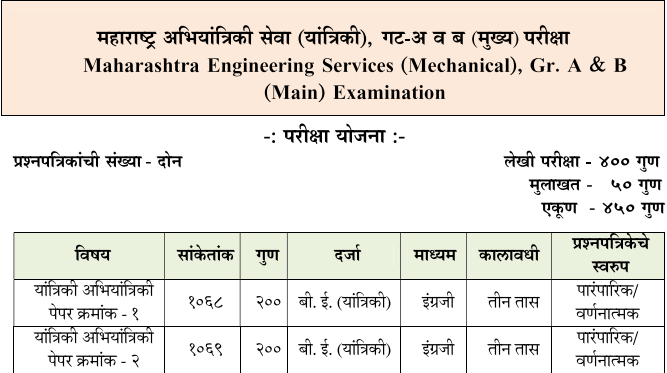

MPSC Mechanical Gr A And GR B Syllabus PDF – The MPSC Mechanical Engineering New Syllabus has been issued. Maharashtra Mechanical Engineering Services Group A and Group B Mains Exam Pattern and Syllabus has been published by MPSC on its official website @mpsc.gov.in. MPSC Mechanical Mains Exam Written exam is of 400 Marks. Candidates all over Maharashtra who have BE in Mechanical as a qualification are eligible to apply for Maharashtra Mechanical Engineering Exam 2024. For this you will need syllabus and Exam pattern details, which is discussed in this section. MPSC Mechanical Engineering Services Syllabus And Exam Pattern 2023 and latest changes in MPSC Mechanical Mains Syllabus, MPSC Mechanical Gr A And GR B Syllabus PDF is given below :

MPSC मेकॅनिकल इंजिनीअरिंगचा नवीन अभ्यासक्रम जारी करण्यात आला आहे. महाराष्ट्र यांत्रिकी अभियांत्रिकी सेवा गट A आणि गट B मुख्य परीक्षेचा नमुना आणि अभ्यासक्रम MPSC ने त्यांच्या अधिकृत वेबसाइट @mpsc.gov.in वर प्रकाशित केला आहे. एमपीएससी मेकॅनिकल मुख्य परीक्षा लेखी परीक्षा 400 गुणांची असते. संपूर्ण महाराष्ट्रात मेकॅनिकलमध्ये BE केलेले उमेदवार महाराष्ट्र मेकॅनिकल इंजिनीअरिंग परीक्षा 2023 साठी अर्ज करण्यास पात्र आहेत. यासाठी तुम्हाला अभ्यासक्रम आणि परीक्षा पॅटर्न तपशील आवश्यक असतील, ज्याची या विभागात चर्चा केली आहे. MPSC यांत्रिक अभियांत्रिकी सेवा अभ्यासक्रम आणि परीक्षा पॅटर्न 2024 आणि MPSC मेकॅनिकल मुख्य अभ्यासक्रमातील नवीनतम बदल खाली दिले आहेत:

तसेच या संदर्भातील पुढील सर्व अपडेट्ससाठी या लिंक वरून आपण आमच्या टेलिग्राम चॅनलला जॉईन करावे किंवा या लिंक वरून महाभरती एक्सामची अधिकृत अँप आपल्या मोबाईल मध्ये डाउनलोड करावी आणि अधिक ताज्या आणि अधिकृत महाराष्ट्र परीक्षेच्या अपडेटसाठी MahaBharti.in/exam फॉलो करा:

MPSC Mechanical Gr A And GR B Exam Pattern 2024

MPSC Mechanical Gr A And GR B Syllabus PDF

Mechanical Engineering – Paper -1

| Sr. No. | Topic |

| Section-A : Materials and Their Behavior | |

| 1 | Engineering Materials : Crystalline structure of metals and alloys, defects in crystalline materials, Iron-Carbon equilibrium diagram, plain carbon steel, alloy steel, cast iron and types, Brass and Bronze, Aluminum, lead, Tin, Zinc- their properties and applications, Plastic deformation, bearing materials, plastics, ceramics, composite materials, Heat treatment of steels. |

| 2 | Fundamentals : Force, moment, couple, resultant of forces, Equilibrium of forces, friction and friction angle, columb friction, rolling friction and belt friction, frictional torque in pivot and Collar bearings, M.I., Work and energy. |

| 3 | Strength of Materials : Normal and Shear stresses, Stress-strain diagram, thermal stresses, shear force and bending moment diagrams, bending stresses in solid, hollow and built up sections, deflection of beams, shear stress distribution diagram, strain energy, torsion of bars, shafts and helical springs, Deflection of beam under different conditions, impact load. |

| 4 | Theory of Machines : Kinematic link, pair, chain, Mechanism and structure, degrees of freedom, Cams, Gear trains, fluctuation of speed and energy in flywheel, Gyroscope, Balancing of rotating machines, Static & Dynamic balancing, Balancing of Single and multi-cylinder engines and V-engines, belts and chain drives, Hydrodynamic bearing. |

| Section-B : Machine Design | |

| 5 | Design of Elements: Theories of failure, factor of safety, combined stresses. Pressure vessels, struts and columns. Design of Screw and bolt, riveted, welded joints, power screw, Design of Shafts and springs, keys, couplings. Design of clutches and brakes, design under fatigue loading, stress concentration, reduction in stress concentration, S-N curve, Soderberg & Goodman diagram, modified Good man diagram, fatigue under combined stress. |

| 6 | Design of Gears: Spur, helical, bevel and worm |

| 7 | System Design: Design of mechanical systems, specification of components, Design of system including material handling systems, power plants, refrigeration and air conditioning systems, pneumatic and hydraulic systems, etc. |

| 8 | Dynamics of machines: Inertia force analysis, law of gearing, interference and minimum number of teeth, Longitudinal – transverse and torsional vibration, single degree freedom -undamped free, damped, forced vibrations, whirling of shaft- critical speed, vibration isolation. |

| Section – C : Manufacturg Science and Processes | |

| 9 | Manufacturing Science : Theory of metal cutting, Merchant’s force analysis, Tool materials, Taylors tool life equation, Machinability, economics, cutting fluids, Chip removal, Calculation of cutting force on single point cutting tools, twist drills, milling cutter, broaches, reamers, Jigs and fixtures. Recent machining methods – EDM, ECM, PAM, Ultrasonic and Laser, etc. |

| 10 | Manufacturing Processes : Casting, moulding- Types, equipments and defects, hot and cold working of metals – blanking, shearing, punching, piercing, coining, embossing, drawing, spinning and forging, Metal joining processes- welding, soldering, brazing, High energy rate forming, electroplating, surface finishing processes. |

| 11 | Manufacturing Management: Production planning and control, forecasting – Moving average, moving range, exponential smoothening, scheduling, assembly line balancing, Inventory Control – ABC analysis, EOQ models, Statistical quality control and TQM, TPM. Elements of cost, job costing, process costing, estimation of machining time. |

| 12 | Operation Research: Linear programming – Graphical and simplex methods, transportation and assignment models, game theory, queuing models, CPM and PERT, Replacement models, value analysis. |

Section – D : CAD / CAM / CAE

- CAD : Overview and benefits of CAD, primitives, 2D / 3D animation, Bazier curves and splines, Wire-frame modeling, surface and solid modeling, kinematic analysis of open and closed loop mechanisms, stiffness matrix, finite element analysis, optimum design, constrained optimization – Penalty function method, computer aided optimum design of gears, bearings and shafts.

- CAM: Types of automation, Steps in NC manufacturing, manual and NC part programming, APT, Machining centres, FMS, Computer Aided Process Planning, CMM, CIMS & its components, Robotics.

- Product Development: Design materials, human factors in design, applied ergonomics, product development processes, concept development process, customer needs, product specifications, concept generation- creative & logical techniques- QFD, conceptual decomposition (functional & physical), two/three dimensional morphological chart, concept evaluation, pugh chart, weighted decision matrix, analytical hierarchy method, product architecture, Configuration Design, Parametric design, Detailed Design- Design for manufacturing and Assembly selection of manufacturing processes, materials, cross sections, principles of easier & economic assembly, legal issues in product design.

- Machine Tool Design: Kinematics of machine Tools, structural and ray diagrams for speed, stepped and step less regulation of speed, static and dynamic rigidity of machine tools, Vibration of machine tools, chatter, Slide ways and guide ways.

Mechanical Engineering – Paper – II

Section – A :- Thermodynamics, Heat and Mass Transfer

| Thermodynamics: |

Fundamentals- Work, Heat, Zeroth law, First law- application to thermodynamic system components, efficiency, Second law (theoretical treatment only)- quality of energy, increase of entropy, availability and irreversibility, applications, Third law. Ideal gas, real gases, compressibility factor, Joule – Thomson Coefficient. Gas power cycles- Air standard work output and efficiency, mean effective pressure, indicated power, brake Power Vapour Power Cycles- Carnot and Rankine, Reheating and regenerative feed heating, Binary vapour cycle, Thermal efficiency and work ratio.Vapour Power Cycles- Carnot and Rankine, Reheating and regenerative feed heating, Binary vapour cycle, Thermal efficiency and work ratio. |

| 2 | Heat and mass transfer:Various modes of heat transfer, Fourier’s, Newton’s and Stefan Boltzman’s law, combined modes, overall heat transfer coefficient. Conduction-Thermal conductivity, factors influencing, measurement, general differential equation, steady state, linear heat flow through a plain and composite wall, tube and sphere, conduction with heat sources, heat transfer from rods, fins of uniform cross section.

Convection- Forced and Natural, Heat Exchangers-Types, performance, analysis restricted to parallel and counter flow exchangers. Thermal Radiation- Black and non black bodies, Kirchoffs law, grey body radiation exchange, Mass transfer- mass and mole concentration. |

| Section-B : Fluid Mechanics and Machinery, Pneumatics and Hydraulics, Power Plant Engineering, Energy Engineering | |

| 3 | Fluid Mechanics: Fluid and flow-definition and types, properties of ideal and real fluids, Continuum concept, Lagrangian and Eulerian approach. Fluid statics, Kinematics and Dynamics of fluid, flow in pipes, Laminar flow of viscous fluids, Turbulent flow, Dimensional analysis, Compressible fluid flow. |

| 4 | Fluid Machinery: Introduction-Classification, energy transfer between fluid and rotor, flow through machines, ideal and actual slip. Hydraulic turbines, pumps, compressors and blowers. |

| 5 | Pneumatics and Hydraulics: Production of compressed air, Pneumatic control-Components and Systems, electro Pneumatic logic circuits, Pneumatic counters, Typical applications, Circuits, Sensors. |

| 6 | Power Plant Engineering : Sources of energy, variable load problem, power plant economics and selection. Steam power plant- boilers, general layout, different systems, turbine auxiliary systems, heat balance and efficiency. Gas turbine power plant -regeneration, reheating, cogeneration, auxiliary systems, operation, Nuclear Power Plants -basic components, power stations. Hydro electric power plant – site selection, arrangement, operation. Electrical systems and instrumentation. |